Installation Guide | Sliders

Follow this step-by-step guide to ensure a smooth installation process. Use the Table of Contents below to jump directly to the section you need. Instructions must be followed for a valid warranty.

📑 Table of Contents

1. Receiving

- Inspect your door immediately after delivery.

- Report any damage to Pinky’s Iron Doors Customer Service within 3 days.

- Keep all original packaging for potential returns.

2. Storage & Handling

- Handle doors with at least 2 people.

- Store in a dry, covered area with fabric padding.

- Remove packaging immediately; do not store with shipping materials.

- Keep doors dry and wipe away moisture promptly.

- Never leave doors uncovered on an active job site before installation.

3. Rough Opening Requirements

- Rough opening should be 1–2 inch wider and taller than the frame.

- Ensure the opening is plumb, level, and square on every side.

- Maintain at least 1 inch clearance around the frame.

- Exterior doors require an overhang and drip edge installed above the frame for water to be diverted away from the top.

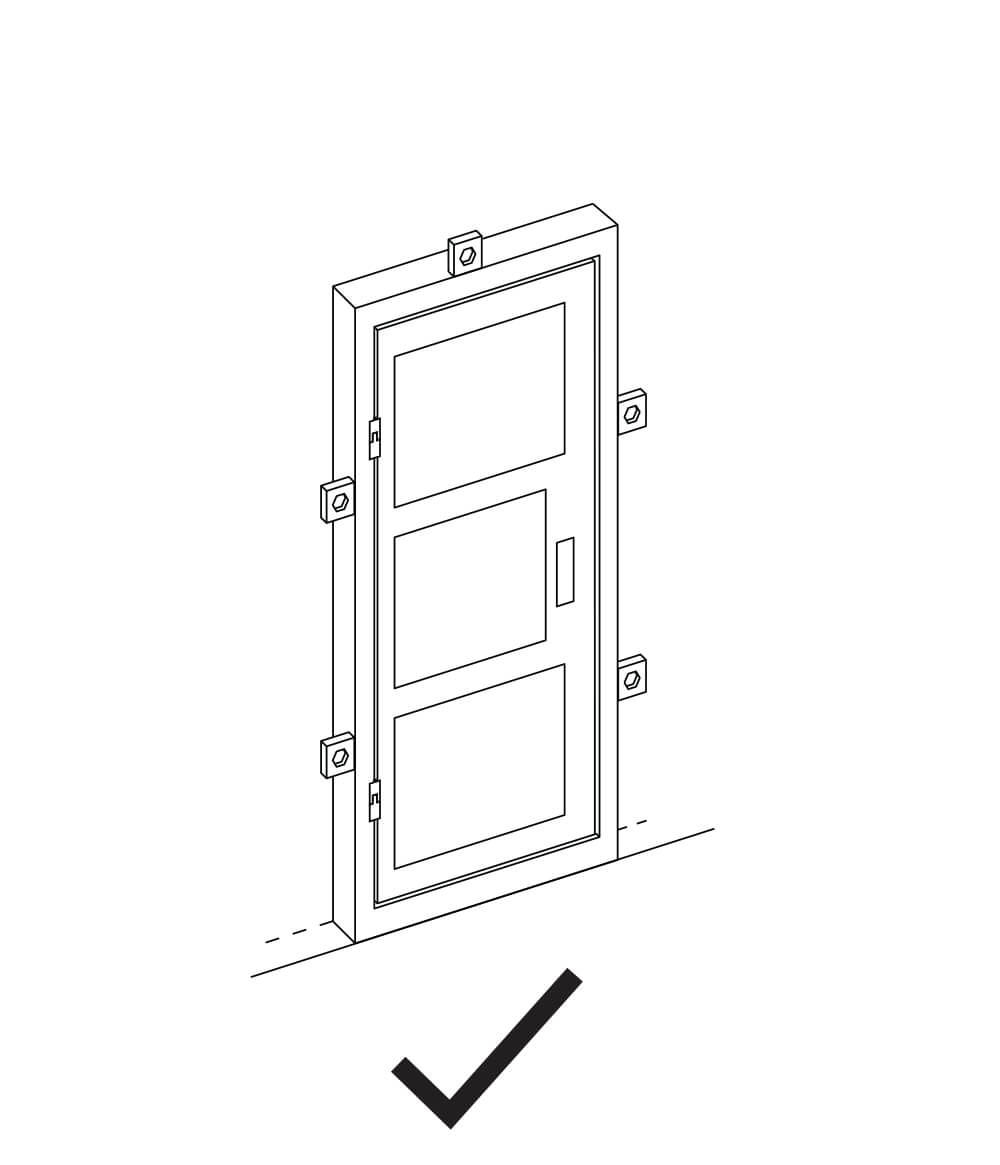

4. Frame Installation

Before you start installing your door frame, make sure your rough opening is plumb, level, and square. Use plastic shims at the leveling points.

- Use only a 12-inch level when installing. Laser levels and long levels are not sufficient.

- Always use plastic shims; wood shims compress over time.

- If using spray foam, it must be low-expanding and applied by a professional.

5. Sliding Door Roller Adjustment and Installation

-

Adjustable Rollers

Each lower corner of the door is equipped with an adjustable roller assembly. These rollers allow the door height to be fine-tuned on each side independently. -

Adjusting the Door Height

Use a 5mm allen wrench to raise or lower each roller. Adjusting the rollers changes the door’s vertical position.- For initial installation, set the roller to its highest adjustment position.

- This provides maximum clearance and makes it easier to place the door onto the track.

-

Installing the Doors onto the Track

Begin by placing the locking side door on the track first. Then proceed sequentially, installing each additional door working outward, away from the first installed panel. -

Leveling

After the doors are positioned on the track, verify your level reference marks. Make fine adjustments to the rollers as needed to ensure the doors are plumb and level. -

Fixed Panel Alignment

It is critical that the fixed (stationary) panel is set perfectly level. This panel serves as the alignment reference for all other sliding panels. Any misalignment here will affect the movement and fit of the remaining doors. -

Installing End Plates

Install the end plates on all sliding door panels. Note: Some minor filing or fitting may be required, as roller positions can vary based on door adjustments.

6. Hardware & Finishing

Adjust lock strike plates if needed. Check roller catch stiffness and adjust screws.

7. Care & Maintenance

- Vacuum dust/debris after installation.

- Protect doors with blue vinyl painter’s tape only.

- After construction, remove tape and apply PINKYS Spray.

- Only blue vinyl painter’s tape on doors/frames.

- Replace tape regularly if exposed to sunlight.

- If duct tape is needed, apply blue painter’s tape first.

8. Troubleshooting

1. Our doors are designed with real, solid metal craftsmanship. Because we apply high heat during welding, the metal shifts slightly during the cooling process and contracts, which means you might notice tiny subtle variations rather than straight lines. This is normal and part of the handcrafting character of our doors. We could force perfect straightness but it would require lots of filler and would compromise the honest metal design. So when you see slight, gentle curvature or variation, rest assured it’s intentional and built into the process.

2. Do not use a level or straight edge on the hinge to check door alignment. The hinge is not a measuring point for our doors. Hinges act as pivot points and are not designed to be perfectly straight. Because of this, placing a level or straight edge on the hinge will always give a false reading. To confirm proper alignment, check the frame is level using a 12 inch level and has the correct clearance gaps around the frame. Adjust shims as needed.

3. If the door rubs, or locks do not align, check frame leveling with a 12-inch level, shim points, and clearance gaps (1 inch). Adjust hardware and shims as needed.

4. Adjusting Door Touch Points and Locking Alignment

If the locking door or first panel is not closing properly, you may need to adjust the frame to correct the alignment. To do this, add shims at the point farthest from the center. This will nudge the door so it will meet the other panel properly and allow them to close and lock together smoothly.